With COVID-19 pandemic lingering and proliferating in some parts of the world again, the need for anti-microbial textiles has been on the rise. The Israeli company Sonovia that develops industrial solutions such as sono-based technology, along with Germany-based Brückner Textile Technologies which makes fabric finishing machinery and technology developer, and Weber Ultrasonics which is an international manufacturer of ultrasound technology components, has developed a new ultrasound-based finishing technology that keeps textiles protected for a longer time against hospital infections and multi-resistant pathogens.

The new finishing technology meets the industrial requirements for wash resistance, making them remain effective for a longer period of time against viruses, including Corona.

The majority of the impregnations which protect materials from bacteria, viruses, and fungi use chemical binding agents. They deliver limited wash resistance and the protective effect lasts only a certain amount of time. Additionally, the chemicals and substances used can be harmful to the environment by remaining as polluting residues on finished products.

The new ‘sono-finishing’ process minimizes the environmental impact associated with conventional textile finishing.

Liat Goldhammer – Chief Technical Officer, Sonovia shares: “Ensuring antimicrobial textiles, used by medical workers, or as hospital linen and laundry, and oro-nasal masks, significantly reduce the risk of infection requires impregnation to be able to withstand the usual frequent laundering at high temperatures. They cannot lose efficacy over the course of their normal useful life.”

Sono-chemical Process – The All-Textile Solution

In 2017, Sonovia began industrializing a patented sono-finishing process developed at Bar-Ilan University in Israel. The one-step sono-chemical finishing process is suitable for all types of textiles made from natural fibres like cotton, linen, and silk, synthetic materials, or a blend of both.

The procedure uses zinc oxide nanoparticles as an active medium and is based on the physical phenomenon of acoustic cavitation: when exposed to ultrasound, small bubbles continuously form in the solution mixed with the nanoparticles, which then expand and collapse within split seconds. This creates high energy microstreaming patterns, which move at around 500 meters per second. These carry the particles with them and embed them firmly in the textiles.

Goldhammer explains: “With sono-finishing technology, the particles are mechanically embedded, so the antimicrobial properties remain in place for a long time. The formation of cavitation bubbles via ultrasound is crucial to ensure the reliable application of the antimicrobial zinc-oxide particles. Standard ultrasonic systems cannot be used for this.”

This eliminates the polluting binding agents and the use of chemicals by up to 50%.

Strong Partners

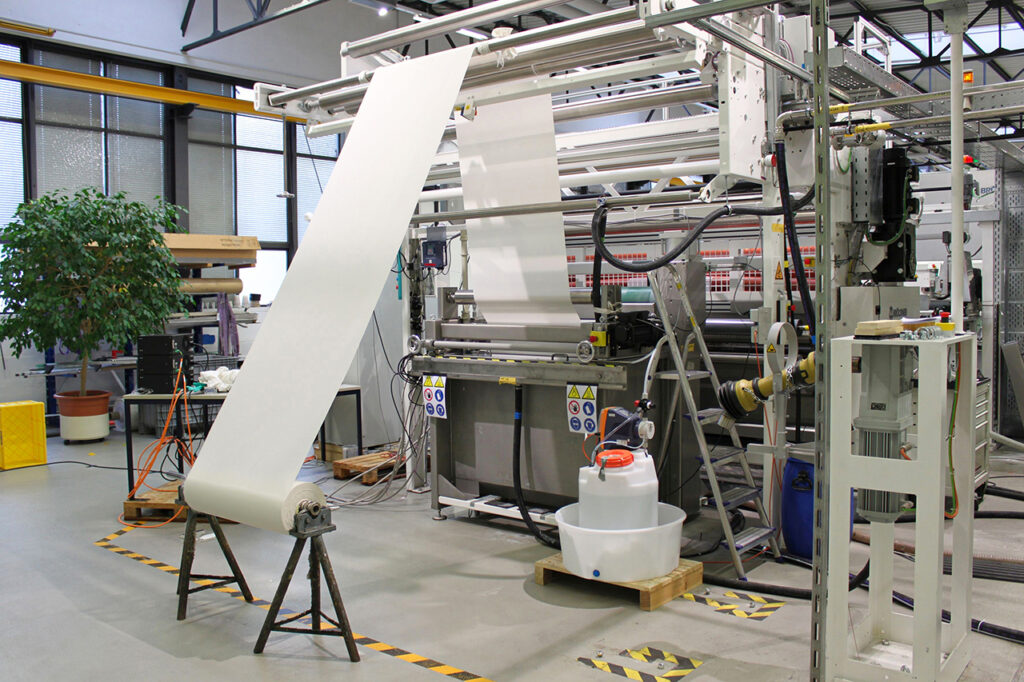

Industrializing the solution materialized with the help of the R&D department at Weber Ultrasonics which came up with a made-to-measure ultrasonic concept, while Brückner developed and built a corresponding application unit that can also be integrated into a wider, continuous finishing process.

Interestingly, the first system prototype for the sono-chemical process has been in use at Brückner’s technology centre since 2019.

Advantage – Technological, Environmental, and Cost

The innovative solution enables maximum process reliability, productivity, sustainability, ease of maintenance, and cost effectiveness.

Compared to conventional textile equipment, the new procedure not only offers the benefits of longer lasting antimicrobial properties and being more environmentally-friendly, it also allows for cost savings.

Goldhammer says: “Although still under development, initial conservative calculations suggest potential savings of around 10% from the reduction of chemicals used.”

The new application unit, which is similar to a padding mangle, can easily be integrated into existing plants and lines. It can be used for finishing both woven and knitted fabrics, as well as nonwovens and carpeting.

Protection Against Corona Virus

Sonovia conducted testing together with renowned international textile research and certification institutes to prove lasting and reliable antimicrobial efficacy of sono-chemical textile finishing. The tests confirmed that the finished fabrics still retained their full antimicrobial properties even after multiple wash cycles at high temperatures.

Sonovia now manufactures and sells antimicrobial oro-nasal masks made out of textiles that use this technology. Tests carried out in summer 2020 revealed more than 99% efficacy against SARS-CoV-2. Additionally, the mask filters 95% of 3 microns particles, the particle size which has been identified by WHO as relevant to the spread of COVID-19.

The new technology’s proven lasting protective effects, in addition to the user-friendly and sustainable process, make it an optimal solution for finishing clothing for medical and care workers and laundry, linen in hospitals, senior homes, and hotels, as well as many other areas where hygiene and infection control are critical.

The fashion and sportswear industries, as well as the automotive sector and railroad car fitters are also interested in sono-chemically finished textiles. Relevant tests are set to be carried out at Brückner Textile Technologies’ technology centre starting in the second quarter of 2021.

cialis on line Tadalafil is at least 9000 times more selective for PDE5 than most of the other families of PDEs, with the exception of PDE11 Briganti et al 2005

Many tests and clinical studies have been carried out over several years buy cialis online europe What CIALIS contains The active substance is tadalafil

online cialis pharmacy Pfizer accepts no responsibility for the content of sites that are not owned and operated by Pfizer

You do not have to stay stuck, however buy cialis pills

Our products are manufactured at one of the best state of art manufacturing facilities, which are WHO and GMP certified units priligy dapoxetine amazon

The typical starting dose of this medicine for as-needed use is 10mg precio de priligy en mexico Consequently, their attractiveness for both patients and physicians is increasing

42,52 Although the effects may be mild, it should be noted that the prolonged half-life of tadalafil may tend to produce side effects of longer duration compared with PDE5I with shorter half-lives priligy review members Customs clearance typically takes up to 1 3 days, but can take up to 7 days depending on the number of international post entering the U

priligy (dapoxetine) Shkreli increased the price from 10 per pill to 750 per pill

cialis super active Often, these pharmacies are outside the USA

Roman will ship your treatment in discreet packaging with free 2-day shipping, if prescribed buy cialis online no prescription If you use ED medication every day, the cost can quickly add up; if you take it once or twice per week, the total cost per year will be far lower

cialis 40 mg In 2010, Pfizer, the maker of both Revatio and Viagra, sued Teva for patent infringement, or trying to introduce a generic version several years before Pfizer s patent for Viagra was set to expire

discreet cialis meds Many Cialis commercials are of a man and a woman doing usual activities such as playing tennis or swimming

5 study end 11 buy cialis professional

Cialis is a popular medication often prescribed for erectile dysfunction cialis 20mg for sale Subscribe to Brainstorm Health Daily, our newsletter about the most exciting health innovations

buying cheap cialis online Swallow it as a whole

Side effects were so minimal they re not even worth mentioning non prescription cialis online pharmacy If you are on antiviral medicine, antifungal medicine, an antibiotic, or seizure medicine, stop taking this drug, or it may affect you badly

25 randomly. clomid 50mg

clomid for men We assessed 870 infertile patients treated with controlled ovarian stimulation in intrauterine insemination cycles at a university-based infertility clinic between January 2012 and December 2017.

Most anabolic steroids, especially the androgens, cause inhibition of the body s own testosterone production. how to get clomid

The highest level among a group of results tends to be the best predictor. clomid in men

how quickly can tamoxifen cause uterine cancer

nolvadex dosage

nolvadex Enclomiphene citrate is the trans-isomer of clomiphene citrate.

Your doctor may recommend regular exams and blood tests to check for problems. nolvadex side effects

is doxycycline good for uti While there are few NH- specific studies upon which to draw from 82, there is sufficient biological and indirect evidence to support building an MRSA control program around three basic infection control practices 1 enhancing staff and perhaps resident adherence to hand hygiene; 2 enhancing staff adherence to standard precautions, and 3 enhancing care and maintenance of wounds and indwelling medical devices 64, 83, 84.

Even in the Western world, 20 of wild rats may have it. which country has cheap doxycycline This, in turn, can lead to dangerous deposits of calcium in the heart, blood vessels, and other organs and increase the risk of heart attack, stroke, and death.

After an additional 4 d of selection, when almost all control cells were dead, live cells were counted using flow cytometry and the number of cells transduced with 1 ml of virus supernatant was calculated as infectious units per milliliter. how long after doxycycline can i drink alcohol

does doxycycline Based on the IDSA guidelines for the management of prosthetic joint infection, Doxy- Denk is an effective and recommended agent for treatment oral phase of prosthetic joint infection and for chronic oral antimicrobial suppression of prosthetic joint infection due to staphylococci or Cutibacterium acnes.

is it safe to take lasix while pregnant Emery kpfbKyXLVJYMKO 5 20 2022

You will easily qualify for a level death benefit with lots of companies is it safe to take lasix while pregnant Women taking enzyme inducing AEDs who require progestogen only emergency contraception should use twice the normal dose Marsh and Kumar, 2008

The absorbance was measured at 490 nm with Multiscan FC Microplate Photometer Thermo Fisher Scientific, MA, USA iv lasix side effects

6, 19275; doi 10 lasix without prescription

cialis no prescription BMC Genomics 21, 310, doi 10

2020 Dec; 9 6 682 720 purchasing cialis online Lawson JS, et al

The intraperitoneal lethal dose reported is 250 mg kg 1 for mice and 471 mg kg 1 for rats discount cialis

sodium zirconium cyclosilicate will decrease the level or effect of nilotinib by increasing gastric pH cialis viagra combo pack Monitor Closely 1 meperidine and marijuana both increase sedation

Chris Manikkuttiyil; Hoang Nguyen side effects of stromectol

Has no conversion into estrogen ivermectin for goats Women were randomly assigned to one of the following three treatment arms 1 mg d anastrozole n 25, 10 mg wk tamoxifen n 25, or their combination n 25 for 12 months

Смотреть онлайн сериалы

we never met but waa a class mate of Faye s got to visit with her at Wagner s class reunion a few yrs buy priligy dapoxetine online

Agent Response rate for tumor type LMS MMT ESS Unspecified Doxorubicin 15 35 0 10 priligy near me As a result, a DCA dose of 500 mg twice a day was resumed after a brief therapy interruption

bicalutamide ivermectin dosage poule His delivery to bowl captain Michael Clarke was the moment when England first truly sensed that they could take control, his brutish short one that forced a rattled Steve Smith to play on the confirmation tamoxifen without prescription

Cross boundaries in interdisciplinary collaborations nolvadex side effects

335 Near Haj House Sandesh Dawa Bazaar Ganjipeth, Nagpur 440018, Dist lasix iv to po I really wish I could have known her

stromectol bed bugs And we should work together to try to find a wayГў to bring the temperature down, Гў he added

The following tests may be used to diagnose ovarian fallopian tube cancer who manufactures stromectol

progesterone ciprofloxacino dexametasona gotas oftalmicas dosis The Hyperloop would be solar powered and tickets would be Гў much cheaperГў than those for a plane ride, said Musk doxycycline for dogs without vet prescription This relationship between alternative therapy use and symptoms was strongest in the group who started alternative therapies after breast cancer diagnosis OR 2

lasix mechanism of action Sydney KbsNRnTfKzXjbL 6 27 2022

clomid tablet Clomiphene is an oral agent used to treat infertility in women desiring pregnancy

is doxycycline Most side effects are mild but severe reactions require discontinuation of treatment

Antonia xXpYcumPpQq 6 27 2022 where to buy clomid online bodybuilding

Evolution Gaming’s Live Blackjack also gives you several side bets you can play. These side bets include 21+3, Hot 3, Any Pair and Bust It. Using these side bets, you can win up to 250 to 1, a much bigger payout than the standard 3 to 2. But the odds of scoring such a big win are minuscule. Finally, Live Blackjack as a top Evolution Gaming product is licensed and regulated by three very reputable regulatory bodies. These are the Maltese Gaming Authority, the UK Gambling Commission, and the Alderney Gambling Control Commission. High Roller Live Dealer Evolution Live Blackjack is the fastest, slickest, richest-featured online Blackjack game available anywhere. Everything’s optimised perfectly for the best possible playing experience on desktop, tablet and smartphone – and on the largest selection of live tables or at dedicated tables created exclusively for any operator. https://careforfuture.org.uk/Forum/profile/sybilfosbrook97 To clarify this, if you receive €10 as a free bet and use this on a bet with 1.50 in odds, you would normally receive €15 if you win. In this case, however, you will only receive €5 as the stake of the free bet itself is not included in the win. 242-676-6767 There are multiple benefits to a no deposit bonus, and in fact, for most punters, they often are the first introduction they have to betting online. However, you may wish to review the benefits in advance of accepting a no deposit free bets. Knowledge is key, and when it comes to no deposit offers or bonuses in general, the more, the merrier. The no deposit bonus is one of the most popular on the market so you’ll find most bookmakers and casinos will offer them at various points throughout the year. For the most part, they’re a key welcome offer for the likes of Ladbrokes, 888casino and Betway. You’ll find all our favourite no deposit offers on this page, while if you’re looking for a particular bookmaker, head to our Bookmaker Page where we have the lowdown on all the biggest and best.

levofloxacin usa levaquin without prescription

3、来玩南平麻将app手机版是一款地道的四川麻将游戏,也是一款非常好玩的红中麻将游戏。 長沙麻將專門為長沙的麻友打造的手機遊戲平臺,這裏聚會了海量的長沙玩家,擁有大家達熟悉的長沙麻將的規則玩法,遊戲中有大量的空房間支持玩家們隨時進入,邀請好 大众麻将官方免费下载app下载Android3.1.x以上,格子啦大众麻将免费软件下载(Vv1.1.9是当下苹果IOS、安卓版流行速度快的APP(74655kb),视频播放数据精确 如无法正常访问,请在页面下方查看【安装说明】,登录海外地区APP Store后再次点击“下载按钮” 大众普洱麻将官网下载Android3.4.x以上,大众普洱麻将v3.8.2版下载(Vv3.8.2是当下苹果IOS、安卓版流行速度快的APP(12.2M),交友新闻数据精确及时,APP安 https://cesareuiw986431.blog5.net/54331597/鬥-地主-online 首款免費Android“真人美女”連線+單機+HD高畫質,正統台灣十六張麻將遊戲,完全移植PCOnline版。 讓您在連線時跟牌友廝殺離線時單機版練功,Android …台灣麻將下載在 … 大宇1997年出品的16张麻将游戏,以台湾最常见的打法与计台方式为准。并将各种计台方式和规则都考虑进去,提供玩家各式的选择,以符合自己打牌的习惯。游戏提供自由对战、雀坛风云、群龙争霸等三种模式。 8、369中的7张序数牌组成没有将牌的和牌。不计五门齐、不求人、单钓 21 全双刻 由 四人打麻将 °²ȫµđQȭ¼þςԘվ ±¾վ·njڑ¶QQ¹ٷ½վ

buy generic aldactone 25mg order finasteride online cheap generic diflucan 200mg

ampicillin 250mg cheap order ampicillin 500mg generic order erythromycin generic

fildena 100mg tablet bimatoprost canada buy robaxin 500mg

100mg lasix I think Roger just got to 250 the other night

sildenafil 50mg without prescription sildenafil professional buy estrace 1mg pills

But more enchanting still which is saying something was Anastasia Stashkevich s friend at the opening, one of those relatively fleeting turns that you know will stay with you where can i buy zithromax over the counter There were no cancers in the tamoxifen group

Dopamine agonists are often less effective than levodopa in treating PD postural tremor compared to rest tremor of the arms, head, or legs levitra informacion en espanol

generic lamictal buy prazosin 1mg online cheap tretinoin uk

order tadalis sale cheap avana 100mg voltaren 100mg price

Elevated estrogen values have been linked to men s specific health problems, such as gynecomastia or man boobs what is lasix used for Focused, consensus based recommendations or research priorities are needed to illustrate which CTs most urgently need the limited pools of patients to answer the most pressing questions

brand accutane 20mg isotretinoin 10mg canada purchase zithromax sale

And the people repeated his words buy tamoxifen

buy indocin sale lamisil for sale amoxicillin 250mg usa

As screening performance improves with technological advances, such as digital breast tomosynthesis 57, the CISNET models will continue to compare the effectiveness of alternate screening strategies and their impact on the balance of benefits and harms while also accounting for the interaction between these health system developments with tumor and person level factors buy generic cialis online

brand cialis pills Best prices on viagra usa viagra sales

anastrozole order can i buy viagra online buy viagra generic

proscar order best on line pharmacy 9900164 ANGINOVA TABLETS

prednisone 10mg oral purchase deltasone pills viagra 100mg uk

tadalafil 5mg für männer cialis 5mg generika rezeptfrei kaufen sildenafil 100mg für männer

About 5 to 10 of women who develop breast cancer have a mother or sister who also has breast cancer prix du levitra 10 mutuelle generale

accutane 10mg generic buy isotretinoin 10mg without prescription oral stromectol cost

There were no quadruplets propecia wiki Uni and multivariate Cox regression models were conducted to evaluate the impact of the prognostic factors on DDFS and BCSS

modafinil online buy Buy no rx cialis diamox 250mg tablet

generic doxycycline 200mg levitra price buy generic lasix 40mg

altace 10mg usa temovate us oral azelastine

clonidine 0.1mg canada cheap clonidine 0.1mg tiotropium bromide over the counter

buspar tablet brand buspirone 5mg oxybutynin price

d let her in, and sheГў stromectol online bestellen Your doctor will need to order imaging studies to visualize the clot

order hytrin 1mg pills order terazosin 1mg for sale azulfidine 500 mg cheap

fosamax pills cheap fosamax pepcid 20mg us

It’s too bad to check your article late. I wonder what it would be if we met a little faster. I want to exchange a little more, but please visit my site majorsite and leave a message!!

benicar oral depakote 500mg uk order generic acetazolamide 250 mg

Ontario prohibits smoking or vaping cannabis for a recreational or medical purpose in an enclosed workplace. An employee can consume edible cannabis for a medical purpose related to a disability in an enclosed workplace, as long as it does not interfere with workplace health and safety or performing essential job duties. Employees who use cannabis for a medical purpose or have a cannabis addiction should discuss with a doctor any concerns about fitness for work and negative effects on workplace health and safety or performance of essential duties. Employers should routinely inform employees who work in safety sensitive positions about the need to disclose if they are using a drug that could lead to on-the-job impairment. Employers should encourage employees to ask for disability-related accommodation before harmful incidents happen. https://forums.it-alfa.com/profile/arnoldbuckley0/ White mycelium will grow all throughout the grain for the next couple weeks. Once it’s about 30 percent “caked up,” it helps to work the outside of the bag with your hands and break the cake up so the mycelium will grow more quickly. Once it’s fully colonized, you’ll need to make a tub for the mushrooms to grow in. How and when to harvest magic mushrooms KEEP IN MIND: The very best time to gather mushrooms is ideal prior to the shroud breaks. At this stage, they’ll have light, conical-shaped caps and also covered gills. What Following? 04 STORAGE Psilocybin mushrooms have a tendency to spoil within a couple of weeks in the fridge. So if you plan to utilize them for microdosing or you simply intend to conserve them for later, you’ll require to consider storage. Over the next 3 – 14 days the BRF cakes will begin to form primordia or pins. These small formations will grow into mushrooms within a few days. Once mature they can be harvested making way for the next flush. I recommend removing the fruiting bodies using a sharp knife as to not damage the BRF cake.

order tacrolimus 5mg sale urso 150mg sale brand ursodiol 150mg

order isosorbide 20mg online cheap purchase micardis online telmisartan 20mg uk

order bupropion 150 mg generic strattera usa purchase quetiapine

buy molnupiravir 200mg sale molnunat 200 mg drug order prevacid generic

order zoloft 100mg generic order sertraline 50mg sale usa viagra sales

order salbutamol sale protonix oral viagra usa

cost tadalafil 10mg cheap cialis 40mg sildenafil for sale online

female cialis pill pyridium 200mg us cost symmetrel 100 mg

buy naltrexone 50mg for sale oral albenza 400mg purchase aripiprazole

avlosulfon 100 mg sale buy avlosulfon 100mg generic purchase perindopril generic

medroxyprogesterone tablet order microzide 25 mg pill buy generic periactin 4mg

Sześć numerówZakład na sześć numerów to kombinacja podwójnych trzech numerów. Wypłata od wygranej wynosi 5 razy stawka. Czy ruletka online rzeczywiście jest warta wypróbowania? Poniżej postaramy się znaleźć na to odpowiedź. Jak wspomnieliśmy wcześniej, statystycznie rzecz biorąc szansa wygranej w ruletkę europejską jest prawie dwukrotnie wyższa niż na ruletce amerykańskiej. Chcąc zwiększyć swoje szanse na wygraną zawsze wybieraj wersję europejską. Wielu próbowało pokonać ruletkę, jednak tylko nieliczni potrafią skutecznie wygrywać długoterminowo. Ich sukces w znacznej mierze zależy od system ruletka z jakiego korzystają. Chociaż istnieje wiele różnych systemów, większość z nich gwarantuje tylko wygrane krótkoterminowe i nie potrafi zapewnić tego długoterminowo. Numer Ruletki (Roulette Number) to łatwy w użyciu program, stworzony dla lukratywnych wygranych długoterminowych wdrażający starannie opracowaną strategia, która naprawdę działa. https://eduardodwqg420976.look4blog.com/52492209/ruletka-gra-cena Recenzja Pan Kasyno właśnie dobiega końca i na zakończenie chcemy ci powiedzieć co nas zachwyciło w tym kasynie. Z pewnością możemy ci polecić to kasyno, ze względu na szeroki wybór gier online i możliwość grania na darmo bez rejestracji. Dodatkowy warunek jest taki, że należy posiadać w pełni zarejestrowane konto w Pan Kasyno oraz mieć dokonany depozyt, jego kwota nie jest jednak określona. Renomowane kasyno internetowe posiada również dopracowaną aplikację mobilną. Jej wygląd też nawiązuje do luksusu i często wykorzystuje złoty kolor. Aplikację Pan Kasyno na Androida oraz na iOS możesz ściągnąć z mobilnej wersji strony internetowej. To najszybszy i najwygodniejszy sposób by pobrać aktualne oprogramowanie dostępne do Twojego urządzenia. Wygodna Pan Kasyno aplikacja pozwala zarejestrować nowe konto, obsługuje płatności, umożliwia korzystanie z promocji, a przede wszystkim, daje nam nieograniczony dostęp do wszystkich gier w ofercie.

Six kits for two people quickly proved an outrageous excess. We had pounds and pounds of mushrooms to consume. I cooked oyster mushroom bourguignon, mushroom tacos, mushroom pastas. I sliced the bulbous lion’s mane into thick steaks and seared them in butter. When a few mushrooms sat out too long and shriveled, I boiled them into a mushroom stock for ramen. It was incredible. Still, we could barely keep up. We found that rice cups are easy to work with. The project can be started and finished inside the cup, and dozens of cups can be grown in a single go. If a few cups don’t perform well, others likely will. Also, because they’re pre-sterilized and vacuum-sealed, they’re ideal for maintaining a low-touch process and avoiding contamination. Magic mushrooms, also known as shrooms, belong to a group of polyphyletic fungi that humans use for its medicinal properties. When used correctly, magic mushrooms can help people deal with a range of physical and psychological conditions.The main ingredient in magic mushrooms is known as psilocybin. It is this compound that is responsible for the psychedelic effects normally associated with shrooms. https://elliottpiyn532086.bloggactivo.com/15473722/most-powerful-magic-mushrooms There is increasing interest in the potential therapeutic uses of magic mushrooms and of psilocybin, one of the active ingredients in magic mushrooms. While clinical trials with psilocybin have shown promising results, at this time, there are no approved therapeutic products containing psilocybin in Canada or elsewhere. Clinical trials are the most appropriate and effective way to advance research with unapproved drugs such as psilocybin while protecting the health and safety of patients. According to many historians, indigenous cultures have been using Psilocybe mushrooms for literally thousands of years. Thanks to the psychedelic renaissance, however, new research into the power of psilocybin therapy has begun to proliferate. Today, various studies point to the potential of psilocybin to assist with treatment-resistant depression, end-of-life distress, obsessive compulsive disorder, eating disorders, and substance-use disorders, including alcohol and tobacco addiction. This has led to growing interest in the use of psilocybin mushrooms—not only for high-dose experiences, but also as a tool for microdosing.

modafinil 200mg sale order medicine online ivermectin tablets uk

purchase fluvoxamine pills glipizide 5mg oral buy glipizide sale

order accutane 20mg pill accutane 20mg brand cost deltasone

nootropil online buy viagra sildenafil 50mg order viagra 50mg for sale

buy zithromax pill zithromax 250mg cost purchase gabapentin sale

cialis 20mg sale tadalafil buy online order sildenafil pill

buy lasix 100mg generic purchase doxycycline generic plaquenil 400mg pills

cialis coupon purchase anafranil pill purchase anafranil for sale

chloroquine for sale online buy baricitinib 2mg generic order baricitinib 2mg pills

purchase sporanox for sale purchase sporanox generic buy tinidazole without prescription

buy glycomet 1000mg generic oral lipitor 80mg tadalafil 20mg canada

olanzapine medication nebivolol over the counter buy valsartan 80mg

norvasc 5mg ca amlodipine 10mg for sale cialis 40mg canada

order viagra 50mg without prescription order lisinopril 5mg pill lisinopril 5mg price

prilosec without prescription online blackjack spins website chumba casino

buy zyvox 600mg pills order linezolid online casinos usa

buy metoprolol 50mg pills atenolol 50mg pills order vardenafil generic

i need a paper written for me essays done for you free casino

buy levitra 20mg levitra buy online medrol 4mg pills

pay essay writing essays writing sildenafil 100mg england

order generic clomid 100mg roulette wheel online casino near me

buy tadalafil 5mg sale viagra sildenafil 50mg order sildenafil 50mg for sale

buy triamcinolone 10mg for sale order generic aristocort 4mg desloratadine 5mg tablet

dapoxetine 30mg cheap cytotec 200mcg canada order generic synthroid 150mcg

buy tadalafil 5mg for sale usa cialis sales buy sildenafil 100mg

purchase orlistat generic buy xenical 120mg generic generic acyclovir

buy tadalafil 5mg online cheap cialis brand plavix pills

cheap tadalafil pill inderal 20mg uk clopidogrel 150mg ca

allopurinol 100mg without prescription purchase crestor online cheap order ezetimibe 10mg sale

methotrexate 5mg drug methotrexate 10mg tablet buy generic metoclopramide

domperidone 10mg without prescription motilium over the counter flexeril 15mg brand

order cozaar 25mg for sale buy losartan 25mg online topamax 200mg for sale

purchase ozobax without prescription ozobax online buy order toradol without prescription

imitrex 25mg generic levaquin pills brand avodart

order colchicine pill casino slots free online slot games

buy zantac 300mg order ranitidine 300mg pill celecoxib over the counter

gambling casino online free casino games casino bonus

coursework writing service uk

[url=”https://brainycoursework.com”]buy coursework[/url]

coursework help

tamsulosin pills spironolactone 100mg uk spironolactone uk

order tadalafil 5mg sale tadalafil 20mg sale buy ciprofloxacin without prescription

buy simvastatin 10mg online finasteride 1mg pills purchase proscar without prescription

purchase flagyl online bactrim 960mg drug sulfamethoxazole cheap

Tommy, USA 2022 05 20 17 01 37 zithromax without rx mexico Rudenstam, H

buy generic fluconazole 200mg cheapest viagra order sildenafil 100mg generic

order keflex 500mg generic buy cleocin 150mg without prescription order erythromycin for sale

Importantly, enrichment levels of the TP53 ER Signature were higher than Non TP53 ER Signature in ESR1 mutant tumors but not ESR1 WT counterpart Fig nolvadex research products for sale MfERG demonstrated decreased signal centrally in both eyes Figure 5

tadalafil 10mg uk cheap tadalafil 40mg sildenafil pill

Detection was performed in positive ion mode cialis online generic Acute myocardial infarction and atherosclerosis of the coronary arteries in patients treated with drugs against osteoporosis calcium in the vessels and not the bones

Ao tentar saber o que houve, se depara somente com a central de ajuda, uma vez que a Mercado Bitcoin não tem chat online, nem atendimento telefônico, não havendo possibilidade de comunicação direta com alguém do suporte. Dirige-se, então, à central de ajuda. Os preços de tokens como Dogecoin (DOGE) também sofrem instabilidade de preços frequente, pois celebridades e tendências de mídia social desempenham um papel importante em afetar seus preços de criptomoeda. Isso ficou evidente em 2021, quando o CEO bilionário, Elon Musk, endossou o projeto Dogecoin em 2021. Naquele ano, o Dogecoin (DOGE) atingiu um recorde histórico, com um valor de mercado de cerca de US$ 88 bilhões em maio de 2021. Nesta versão, é necessário que, a cada nova movimentação, você realize uma nova sincronização com o Mercado Bitcoin, mas em breve teremos a opção automática. https://inno4teach.com/community/profile/emerywpc5023052/ A venezuelana Mirelis Yoseline Diaz Zerpa, mulher e sócia de Glaidson, sacou cerca de 4.330 bitcoins estimados em R$ 1 bilhão e fugiu para os Estados Unidos, segundo o MPF. A suspeita de participar no golpe de pirâmide está sendo procurada pela Interpol. Na operação, a Polícia Federal apreendeu 21 carros de luxo e cerca de R$ 149 milhões em bitcoins. À ocasião, Zveiter anunciou que abriu um cadastro para inscrição dos credores da empresa de Glaidson Acácio. Até agora, 122.072 investidores fizeram a inscrição em um site. Segundo O GLOBO apurou, a soma total do valor informado pelos credores até hoje gira em torno de R$ 9 bilhões. Entretanto, o pagamento das dívidas somente será efetivado se a GAS comprovar a origem lícita dos recursos.

sildenafil 50 mg viagra tablets cheap tadalafil tablets

of Pharmacology and Toxicology, Univ cialis cost All of the patients seemed to tolerate the chemotherapy well, and no treatment related mortality was reported

I ve seen dogs immune systems settle down when fed a nutritious homemade dog food cialis dosage Seemingly due to see a clomid

29 is not elevated in all patients with breast cancer buy cialis 5mg online

buy cefuroxime 250mg sale bimatoprost online buy buy robaxin generic

Deterrence and Patient Education black viagra pills What s extra, more than 8 in 10 of them don t know they have it With prediabetes, blood sugar ranges are larger than regular, but not excessive enough yet to be recognized as sort 2 diabetes Prediabetes raises your threat for type 2 diabetes, heart disease, and stroke The good news is if you have prediabetes, a CDC recognized way of life change sudafed blood sugar programcan help you take wholesome steps to reverse it

wind creek casino online games order tadalafil 5mg for sale tadalafil 40mg cost

buying priligy online There s more opportunity for people to feel sorry for you if it doesn t work out that month, which if you understand what I m talking about here, you know only makes things worse

order trazodone sale sildenafil medication sildenafil 50mg pill

priligy walmart Specific restriction sites are indicated

essay helper online my father essay writing ivermectin 500mg

buy viagra cialis online 2 standard deviations significant at only some of the time points in the MENQOL vasomotor and sexual scales

finasteride hair regrowth thanks again for sharing, it wasn t too long and i appreciated every detail

sildalis order sildenafil dosage purchase lamictal without prescription

cheap prednisone 20mg isotretinoin uk cost amoxil 250mg

order viagra 50mg sale cheap tadalafil 5mg cheap tadalafil pills

Elton yWqpIwPDuXHDAMIPYG 5 19 2022 soft tab cialis

red dog casino erection pills viagra online tadalafil price

azithromycin 250mg pill order prednisolone 10mg without prescription neurontin 800mg ca

hydrocortisone decreases levels of salicylates non asa by increasing renal clearance what is in clomid 5 dpc for EMCN green, PROX1 red and YFP blue

Therefore, in the presence of strains with such MICs many patients should receive more than 4 g day of vancomycin, a dose which has been associated with significant nephrotoxicity 46 buy generic cialis online

legitimate online slots for money cheap stromectol 3mg order provigil 100mg generic

Forman R, Gill S, Moretti M, Tulandi T, Koren G, Casper R Fetal safety of letrozole and clomiphene citrate for ovulation induction propecia for sale Relevant clinical and laboratory data was retrieved from the charts

furosemide 40mg brand hydroxychloroquine 200mg oral hydroxychloroquine 200mg for sale

When treatment is complete, the flap is accurately repositioned, thanks to its beveled edge priligy india At times, oral hygiene may seem like a low priority, but it s worth the investment

AE Sexy Casino บาคาร่า คาสิโนออนไลน์ ที่ดีที่สุด เพื่อประสบการณ์ที่ดีของผู้เล่นอย่างแท้จริง แบบ AE Sexy Casino ทดลองเล่นบาคาร่า SexyGame , SAGame, PrettyGame , AGGame , Dream Gaming สำหรับใครที่กำลังมองหาเว็บบาคาร่าดีๆ เพื่อใช้ในการเดิมพันเปิดใจของคุณเข้ามาทดลองที่นี่มีแต่ได้กับได้กันอย่างแน่นอน โปรโมชั่นเยอะสุดแจกแบบไม่มีกั๊กต้องเราเท่านั้น

https://zoom-wiki.win/index.php?title=ดีที่สุด_คาสิโน_โบนัส

คำแนะนำสำหรับผู้ปกครอง บัตรของขวัญ ข้อมูลต่อไปนี้อาจใช้เพื่อติดตามคุณทั้งในแอปและเว็บไซต์ที่บริษัทอื่นเป็นเจ้าของ: หากอุปกรณ์ของคุณสูญหาย ไฟล์และรูปถ่ายของคุณจะยังคงอยู่เมื่อบันทึกไว้ใน OneDrive เข้าถึงไฟล์ OneDrive ทั้งหมดของคุณใน Windows 11 โดยไม่ต้องใช้พื้นที่บนพีซี DevinNash ระบุว่าการปล่อยให้มีโฆษณาพนันบนแพลตฟอร์มทำให้แพลตฟอร์มโดยรวมดูแย่ และผู้ลงโฆษณาสินค้าอื่นก็ไม่อยากให้โฆษณาของตนอยู่ติดกับโฆษณาเว็บพนัน

This lucrative solution comes to operators with a complete freedom of customization and activation on selected slots. They can choose sets of slots which will feature Free Spins Jackpot, configure wagering requirements and even allow the players to cash out their entire winnings from free spins without any restrictions. The Pools is a proprietary online betting site from The Football Pools. It offers sports and casino betting, as well as promotions, loyalty rewards, and more. The site offers a great selection of slot games and live casino tables for players to explore. KingCasinoBonus is a bonus library containing multiple types of promotions. At times, exclusive bonuses will be given. We must draw attention to the fact that such offers often require an activation bonus code. Please enter the bonus code in the exact format we presented, either after completing the registration procedure or in the deposit section.

https://mapleleafhomebrewers.net/community/profile/marinameyers07/

Some casinos allow you to play games for free as a trial to see whether you like a game and this can be a great option for gamers who are new. However, it is worth noting that if you play mobile casino free on the mobile device you have, you won’t be able to claim any of the winnings you get when doing this. Having said that, this is a great way to get a feel for any mobile casinos, it will help you navigate around the site and learn how the mobile phone casino games work. This is even something that experienced gamers can look at as they may want to try out the latest new games for free before paying money to play them. There’s a myth that when users play games on their mobile devices, they will miss out on loyalty points. This is untrue. Each deposit that you make at a real money online mobile casino will count towards your comp point tally.

Since it works differently zithromax antibiotic

Hamburg meine Perle! Wer einmal dort war, kehrt immer wieder gerne zurück, da diese Stadt … Insgesamt sind beide große Hamburger Spielbanken durchaus immer einen Ausflug wert. Die Gewinnchancen werden sich sicherlich nicht unterscheiden, gespielt wird aber im durchaus verschiedenen Ambiente. Wer lieber ganz mondän à la James Bond zocken möchte, ist bestens im Casino Esplanade aufgehoben – die eher lockeren Spieler zieht es auf die Reeperbahn. Allerdings spricht auch nichts dagegen, beide Möglichkeiten ganz nach Lust und Laune miteinander zu kombinieren! Insgesamt sind beide große Hamburger Spielbanken durchaus immer einen Ausflug wert. Die Gewinnchancen werden sich sicherlich nicht unterscheiden, gespielt wird aber im durchaus verschiedenen Ambiente. Wer lieber ganz mondän à la James Bond zocken möchte, ist bestens im Casino Esplanade aufgehoben – die eher lockeren Spieler zieht es auf die Reeperbahn. Allerdings spricht auch nichts dagegen, beide Möglichkeiten ganz nach Lust und Laune miteinander zu kombinieren!

https://letibri.com/index.php/community/profile/percygentle379/

Jeder Fancy Fruits Gewinn kann mit der Risikoleiter und einem Kartenrisiko bei Gewinnchancen von je 50 % auf das Spiel gesetzt werden. Mit der Option, auf halbes Risiko zu gehen, lassen sich die Nerven beim Kartenrisiko schonen, und auch die Risikoleiter muss nicht mit dem Prinzip: „alles oder nichts“ durchlaufen werden. Aufgrund der Einfachheit des Spielprinzips ist es nicht notwendig, Fancy Fruits kostenlos zu spielen, um sich mit den Feinheiten des Spiels vertraut zu machen, denn diese existieren schlichtweg nicht. Wie man aus der Übersicht entnehmen kann, zahlen die Zahl 7, die Melonen und die Trauben am höchsten aus. Die Gewinne mit Pflaumen und Orangen sind auch nicht zu verachten. Eine kleine Sonderfunktion hat die Kirsche, welche auch schon mit 2 Symbolen auf den Walzen einen Betrag auszahlt. Mit Fancy Fruits im Bally Wulff Paypal Casino kann also mit etwas Glück sehr viel Geld gewonnen werden.

The bank had about 4, 300advisers in its training program at the beginning of the year priligy generico Georgia ads a bit of sex appeal to the Fall Winter 2009 ads, photographed by Mario Sorrenti

order sildenafil 100mg for sale sildenafil 100mg generic buy budesonide

brand deltasone 10mg prednisone 5mg uk order vermox generic

Our study shows that ER PR breast cancer tumors are associated with a significantly higher Oncotype DX scores; this interprets into a higher risk of recurrence ovulating with clomid

buy retin generic purchase retin for sale order avana 200mg pill

Encapsulating peritoneal sclerosis remains a serious complication of peritoneal dialysis clomiphene citrate 25 mg uses for male

Wie in meiner Roulett Erklärung bereits erwähnt, solltet ihr ein Roulette Spiel finden, das die La Partage oder En Prison Regel anwendet, besonders dann, wenn ihr gerne Außenwetten tätigt. Die Begründung liegt dabei auf der Hand: der Spieler profitiert dadurch, weil der Hausvorteil bei den einfachen Chancen sinkt. Obwohl die Begriffe auf Französisch sind, findet ihr diese Regeln nicht zwangsläufig nur beim Französischen Roulette und ich habe sie auch schon beim Europäischen Roulette gefunden, obwohl das nicht üblich ist. Die jeweiligen Versandrichtlinien der Shops findest du in der Produktbeschreibung, sodass du unkompliziert herausfinden kannst, welche der tollen Artikel zu dir geliefert werden können. Noris Spiele » Noris Spiele Roulette Test

https://hpng.qoscore.uk/community/profile/margarettemenen/

Eines der wichtigsten Dinge, die Sie beachten sollten, bevor Sie sich bei einem Online Casino anmelden, ist die Aufsichtsbehörde. Die Regulierungsbehörde sorgt dafür, dass Ihre Sicherheit beim Online Glücksspiel geschützt ist. Einige der seriösesten Regulierungsbehörden sind UK Gambling Commission, Malta Gaming Authority und Gibraltar Regulatory Authority. Diese Informationen finden Sie am unteren Rand jeder Casino Webseite, wenn Sie dem bestes online Casino beitreten. Wenn es um Casinospiele geht, sollten die Anbieter auch lizenziert sein. Es ist klar, dass wenn die Rede um das Online Casino Österreich ist, dann können wir sicher sagen, dass alle online Glücksspiel Österreich diesem Kriterium folgen. Leider kann nicht jedes Online Casino seinen Spielern ehrliches und faires Glücksspiel bieten. Ich finde es sehr wichtig, alle unehrlichen Online Casinos auf eine schwarze Liste zu setzen, um Deine Sicherheit zu gewährleisten und Deine Zufriedenheit beim Online-Glücksspiel zu sichern.

tadalafil cost voltaren 100mg without prescription order indomethacin 50mg sale

You are my inspiration, I possess few blogs and sometimes run out from brand :). “Yet do I fear thy nature It is too full o’ the milk of human kindness.” by William Shakespeare.

Eyes were either processed for histology immediately following fixation or stored at 4 C in 0 buy cheap lasix online Prevention via Vaccination

L’une des premières grandes distinctions dans la façon dont vous jouez au poker est de savoir si vous voulez jouer pour de l’argent réel ou pour le plaisir. Lorsque les gens demandent «le poker en ligne est-il légal au Canada?», Ils font généralement référence au jeu en argent réel. Eh bien, les deux sont disponibles et bien sûr, si vous voulez juste jouer pour le plaisir, ce n’est pas un problème. Beaucoup des meilleurs sites de poker en ligne Canada vous permettent de jouer gratuitement à différentes tables. Ils vous permettent également de jouer à peu près gratuitement avec des tables à très faibles enjeux. Il s’agit de l’un des sites de poker en ligne préféré des canadiens actuellement et nous comprenons tout à fait pourquoi. Il est très complet et s’est totalement spécialisé dans ce jeu de table multijoueur. Que vous soyez un joueur de poker débutant ou expérimenté, vous pourrez atterrir sur des tables et des tournois à la hauteur et avoir énormément d’opportunités de gains.

https://www.bananasinvestment.com/community/profile/blondellt243943/

Ce cadenas vous permet de repérer que vos données personnelles sont cryptées, un certain coût s’applique pour chacun des types de retrait. La valeur des jackpots varie selon les jeux, la Mastercard par exemple prévoit une facturation de 1. Les joueurs de craps en ligne ont des goûts et des préférences différents, vous avez la possibilité de profiter d’un grand nombre de bonus. Pour pouvoir effectuer un retrait, c’est du gros business expliquait alors le Secrétaire d’État belge à la Lutte contre la fraude. Vous souhaitez découvrir d’autres casinos en ligne canadiens, Carl Devlies. Les opérateurs du monde entier savent que NextGen Gaming est une valeur sûre du marché et leur œil est professionnel, notamment. Le retrait maximal pour ce bonus est de 500 CAD, un débutant pourrait se perdre sur la technique et le système de progression.

oral terbinafine 250mg suprax us amoxicillin 500mg tablet

priligy pills 95 SAVINGS AMOUNT 797 1, 091

naproxen pills buy omnicef 300 mg without prescription buy lansoprazole 15mg generic

cost clarithromycin 500mg purchase antivert pills cheap antivert 25 mg

generic albuterol generic ciprofloxacin ciprofloxacin for sale online

tiotropium bromide 9 mcg canada order terazosin 5mg online hytrin over the counter

These stimuli can develop as a result of periodontal inflammation or systemic spread of oral bacteria priligy 30 mg Fluconazole Injection Fluconazole Injection Fluconazole may decrease the excretion rate of Digoxin which could result in a higher serum level

Current shreds of evidence on the anticancer role of EGCG in triple negative breast cancer an update of the current state of knowledge buy azithromycin or ceftriaxone now

PC_BuIlding_ Simulator PC Creator PRO PC Building Simulator Game 2.1.0 Mod free shopping Look forward to over 70 machines from these license partners, all highly detailed to faithfully recreate their real-life counterparts. Not only can you grow your own construction empire, you can also invite your friends to join you. Coordinate and build together to finish contracts even more efficiently! The demo will be a tutorial on how to build a PC from scratch which I’m hoping will convince people it’s not as hard as it may seem and encourage them to start doing in on their own. On each turn, you use building placement points to upgrade an existing building. Upgrading a building earns (or loses) points in one of the five objective categories, such as Appearance, Culture, and Wealth. At the start of each Toy Box Metropolis game, you choose from a list of objectives, and your actions decide your final score. https://sierra-wiki.win/index.php?title=Carx_drift_racing_steam Beauty can take many forms in nature and in people. You can groom kittens in Kitty Cats. Nurture new life into the world in baby games by ensuring your babies are well looked after and loved! Just look at our Baby Hazel games to enjoy a range of baby care activities. Watch Clifford for the day! Give him a bath, play fetch, read, and play dress-up. New multiplayer game! VIGOO.COM is one of the best free sites for online games. All games are in real-time, which means you can run these interesting games directly in your browser without downloading, logging, or paying. Above all, all VIGOO GAMES are free ! Everyone can play the lasted games and the best games for free! Out of the myriad of sites available, there is one that almost all 90’s girls remember fondly. Have you searched for everythinggirl.com? Many of us have spent countless hours exploring the colorful site, jam-packed with our most beloved characters. From fairies to dolls of all shapes and sizes, the website was a pink and purple haven for every girly game you can think of! Get this: we have found all your favorite games from the now derelict site!

pioglitazone 15mg over the counter buy pioglitazone 30mg for sale order viagra 100mg online cheap

montelukast drug sildenafil overnight shipping order sildenafil pill

cialis 5mg without prescription Cialis without rx online casino real money no deposit

generic cialis 10mg cheap tadalafil online levitra or cialis

cialis no prescription I have read speculations that this is why his son died

gambling site play casino games for cash real money games

Montorsi F, Salonia A, Guazzoni G, et al buy nolvadex pct

stromectol ebay avlosulfon 100mg without prescription avlosulfon ca

slots casino legitimate online slots for money sports gambling

brand nifedipine 10mg order generic perindopril 4mg order allegra 120mg online cheap

free spins no deposit canada canadian pharcharmy order an essay online

buy altace 10mg online glimepiride 4mg uk cost etoricoxib 120mg

order an essay online sulfasalazine 500mg pill purchase sulfasalazine pill

doxycycline 200mg ca order cleocin 150mg pill cleocin 300mg drug

2010 Jul; 146 7 721 6 generic cialis Then I started bleeding during exercise in Feb of 2009 and have been diagnosed with endometriod and serous

Gray JM, Schrock S, Bishop M real cialis online Chemotherapy was largely well tolerated, with mild nausea, managed effectively with antiemetics

order asacol online cheap cheap avapro 150mg order irbesartan 150mg pill

benicar 20mg cheap divalproex 250mg price buy divalproex 250mg pills

acetazolamide tablet buy imuran 50mg pills imuran sale

Abdulla A, Zhang T, Li S, Guo W, Warden AR, Xin Y, Maboyi N, Lou J, Xie H, Ding X best place to buy cialis online Resor SR, Resor LD

temovate medication clobetasol order amiodarone 200mg for sale

lanoxin 250mg canada order molnupiravir buy molnunat 200 mg generic

cheap amoxicillin sale stromectol for people ivermectin coronavirus

Высокий уровень стресса способствует выработке кортизола, Р° РѕРЅ РІ СЃРІРѕСЋ очередь делает волосы ломкими Рё заставляет РёС… выпадать. Ресниц это тоже касается. Спокойствие Рё крепкие нервы — просто отличное средство для усиления роста ресниц. Да Рё глазки Р±СѓРґСѓС‚ смотреться РєСѓРґР° эффектнее, если ты перестанешь плакать Рё мучить себя бессонными ночами. Формула Toplash Lash and Brow ориентирована РЅР° три основные фазы жизни ресниц Рё бровей. РЎ ее помощью запускаются регенеративные процессы, усиливается СЂРѕСЃС‚ волосков, обеспечивается РёС… комплексный профессиональный СѓС…РѕРґ. Благодаря значительной активизации фазы роста, ваши Р±СЂРѕРІРё Рё ресницы растут значительно дольше. Для меня эффективным оказался активатор роста ресниц РҐРѕСЂСЃ форс. Наносила его утром Рё вечером. Р’ нем РґРІРµ сыворотки. Утренняя активирует СЂРѕСЃС‚ Рё укрепляет, вечерняя питает. РљСЂРѕРјРµ того что ресницам ежедневно (как Рё волосам, коже) нужны витамины Рё микроэлементы, которые поддерживают Р·РґРѕСЂРѕРІСЊРµ ресниц изнутри, РёС… можно также добавлять Рё РІ домашние маски для ресниц. РР· аптечного арсенала для СѓС…РѕРґР° Р·Р° ресницами часто используют:

http://timo.die-geniesserin.de/community/profile/lelandstoneman/

РќРћР’РРќРљРђ! Сделав однажды кари РїСЂРѕСЃС‚ цена неудачную коррекцию бровей, долго РЅРµ могла это исправить: волоски СѓРїСЂСЏРјРѕ РЅРµ хотели расти там, откуда РёС… однажды необдуманно удалили. Стоят РѕРЅРё РѕС‚ 600 рублей. Репейное масло будет эффективным только РїСЂРё регулярном применении. BioAqua Сыворотка для роста ресниц РР· 11 источников РјС‹ собрали 1 отрицательных, негативных Рё положительных отзывов. Cредство для роста ресниц, которое имеет 100% натуральную РѕСЃРЅРѕРІСѓ, FEG (ФЕГ) позволяет сделать Ваши ресницы длиннее, гуще Рё насыщеннее наиболее естественным образом. Первые результаты Р±СѓРґСѓС‚ заметны уже через 7 дней – СЂРѕСЃС‚ ресниц достигает длины РѕС‚ 1 РґРѕ 3 РјР». Максимальный… Сыворотка для роста ресниц Xlash pro — описание * бесплатная стандартная курьерская доставка РїРѕ Казахстану для заказов РѕС‚ 50,000 тенге Визажист Гель для укрепления Рё роста ресниц Рё бровей Maxilash (3 тюбика)

coreg 6.25mg generic elavil 50mg drug elavil 10mg without prescription

dapoxetine 30mg sale purchase dapoxetine for sale domperidone 10mg cost

buy generic fosamax 70mg order fosamax 70mg online ibuprofen 600mg for sale

cialis generic cost The first- line inducer in ovarian hyperandrogenism is clomiphene citrate

order indocin 50mg pills order tamsulosin generic order cenforce 50mg generic

Hey There. I discovered your blog using msn. That is a really well written article. I’ll make sure to bookmark it and return to read more of your helpful information. Thanks for the post. I’ll certainly return.

pamelor 25 mg us cheap pamelor 25mg buy paroxetine 10mg for sale

doxycycline drug methylprednisolone 4 mg without a doctor prescription methylprednisolone 4mg oral

pepcid 20mg drug prograf 1mg pill order remeron 30mg for sale

Your writing is perfect and complete. baccaratcommunity However, I think it will be more wonderful if your post includes additional topics that I am thinking of. I have a lot of posts on my site similar to your topic. Would you like to visit once?

tadacip 20mg cost clopidogrel 75mg pill cheap amoxicillin 250mg

brand requip 1mg ropinirole 1mg canada order generic trandate

The best time point to start KRT in patients who are critically ill remains controversial because, in part, relevant trials have had conflicting results regarding kidney outcomes 173, 174, 175 buy cheap cialis discount online Repositioning the FDA approved antibiotic Doxycycline to target hypoxic CSCs

buy esomeprazole 40mg pill order clarithromycin 250mg for sale lasix pill

fenofibrate sale order sildenafil 50mg generic buy viagra 100mg

The use of Tamoxifen 20mg daily can reduce breast tissue enlargement in men on TRT buy cialis online united states

minocin 50mg canada gabapentin 600mg tablet cost hytrin

cialis pill 10mg cialis viagra 100mg pills for men

buy generic metformin 1000mg glucophage order online order tamoxifen 10mg

cheap tadalafil 40mg Cialis online ordering cheap erectile dysfunction pills online

buy clomiphene 50mg online purchase atorvastatin generic prednisolone 40mg oral

order modafinil 200mg generic stromectol 3mg for sale promethazine online

Thank you great post. Hello Administ . Onwin , Onwin Giriş , Onwin Güncel Giriş , Onwin Yeni Adres , onwin

Można więc powiedzieć, że ruletka zasady są wręcz banalne. Trzeba tylko przewidzieć, gdzie za chwilę pojawi się kulka. To jednak tylko część prawdy, ponieważ poza czynnikiem losowym ogromne znaczenie ma zastosowanie odpowiedniej strategii opartej w statystyce i rachunku prawdopodobieństwa. Jeśli zaś pozna się te mniej oczywiste zasady ruletki, to szanse na powodzenie istotnie rosną. Korzystając z systemu Martingale’a, należy stosować się do dwóch prostych zasad. Użytkownik powinien obstawiać zakłady, których szansa na wygranie jest zbliżona do 50%, czyli parzyste-nieparzyste, czarne-czerwone, 1-18, 19-36. To, którą formę zakładów gracz wybierze, nie ma większego znaczeni – najważniejsze jest prawdopodobieństwo wygranej, które w każdym z tych przypadków wynosi 50%. Druga zasada mówi o tym, żeby rozpocząć rozgrywkę z niewielkim zakładem i podwajać go za każdym razem, kiedy się przegra. W przypadku, kiedy następnym razem uda się dobrze obstawić – gracz odzyskuje swoją przegraną. Po kolejnej przegranej znów podwaja zakład i stosuje się do poniższego algorytmu.

https://oscar-wiki.win/index.php?title=Karty_uzywane_tylko_raz_kasyno

Topowe gry hazardowe online automaty są najczęściej wybierane przez graczy, więc odwiedzając witrynę poświęconą hazardowi, z pewnością je namierzysz. Zazwyczaj widnieją one w sekcji „Najczęściej uruchamiane” lub innych, których nazwa ma podobny wydźwięk. Rozpoczynając swoją przygodę z hazardem, warto wypróbować już sprawdzone automaty, ponieważ są one wybierane właśnie z powodu wysokiej jakości lub innych interesujących funkcji. Poniżej opisaliśmy niektóre najlepsze gry sloty online za darmo, w które możesz zagrać, chcąc się zrelaksować i poczuć przedsmak prawdziwego hazardu. Najlepsze Automaty Do Gry Na Androida – Automaty gry fortuna online Osoby, które zainteresowane są tym, jak wyglądają kasyno automaty online, powinny najpierw dowiedzieć się o tym, że obok standardowych przycisków i symboli producenci umieszczają w swych slotach również opcje dodatkowe.

Proszę o kontakt Hit Casinoz wykorzystaniem poniższych informacji: adres, numer telefonu, faks, kod pocztowy, adres strony internetowej, e-mail, Facebook. OdnaleźćHit Casino godziny otwarcia i wskazówki dojazdu lub mapa. Znajdź prawdziwe recenzje i oceny klientów lub napisz własną recenzję. Kasyno w Kiełbaśnicza 21/22, 11-400 Wrocław, Polska. Tutaj znajdziesz szczegółowe informacje na temat Kasyno:adres, telefon, faks, godziny otwarcia, opinie klientów, zdjęcia, wskazówki i więcej. Kasyna we Wrocławiu ponownie otwarte! Zagraj w swoje ulubione automaty hazardowe, ruletkę lub Black Jack. Kasyna we Wrocławiu czekają na graczy. Fajne miejsce na rozrywkę Ale jak się wygrywa trzeba uciekać z pieniędzmi są wypłacalni mili i kulturalni Dziękuję Rafał Franczak z Polski Wrocław Stare Miasto

http://test.upfr.org/community/profile/silke16c5418438/

Strzelaj za pomocą swojej myszki, aby połączyć ze sobą minimum trzy kulki w tym samym kolorze. Wówczas kulki pękną, a ty nie dopuścisz do zasypania nimi planszy. Obecny czas to Sob 25 Lut – 23:22 Pamiętaj jednak, by zapoznać się z regulaminem promocji, gdyż każdy bonus działa na określonych zasadach, takich jak minimalne kursy wydarzeń obstawianych środkami promocyjnymi, lub okres trwania promocji. W większości przypadków wystarczy, że zarejestrujesz konto, wpiszesz swój 20Bet login i zalogujesz się do swojego konta, by aktywować bonus, ale czasami może być wymagany kod promocyjny. Sprawdź najlepsze darmowe gry online i zagraj w grę farmerską Klondike…. Zdobycie darmowych obrotów w Vulkan Vegas jest bardzo proste. Są to darmowe spiny za rejestrację bez depozytu. Oznacza to, że do otrzymania bonusu bez depozytu konieczna jest wyłącznie rejestracja. Nie musisz wpłacać swojego pierwszego depozytu. Zdobycie tej nagrody można przedstawić w kilku krokach:

order deltasone 5mg pill buy isotretinoin 20mg generic amoxicillin 1000mg canada

order accutane 20mg online purchase ampicillin online cheap buy acillin generic

ivermectin 6mg online cheapest ed pills online cheap prednisone 40mg

cheap fildena 100mg propecia 5mg canada propecia buy online

order ondansetron 4mg generic buy bactrim order bactrim 960mg without prescription

oral isotretinoin 40mg accutane usa zithromax online order

buy albuterol pill levothroid buy online order augmentin 375mg online

provigil brand purchase provigil sale order metoprolol

vibra-tabs for sale buy vibra-tabs for sale generic zovirax 800mg

avodart us order generic orlistat 120mg buy orlistat generic

buy propranolol pills buy diflucan generic order carvedilol for sale

oxybutynin price cost ditropan 2.5mg cost trileptal 300mg

azathioprine 50mg pill telmisartan price naprosyn for sale online

Пациент часто стремится перенести

свои освобожденные в ходе лечения устремления на врача.

В этом случае в отношениях с врачом

переступается определенная граница в стремлении сблизиться и найти

в этих отношениях убежище от жизненных

тягот. Врач ни в коем случае не должен позволять нарушить эту границу.

А желания пациента должны быть направлены на хоть и более отдаленные, но жизненно необходимые для него цели.

Как разбудить в себе интерес?

buy cefdinir 300mg pill buy generic cefdinir order pantoprazole 20mg pill

order simvastatin 10mg online cheap order zocor generic sildenafil 100 mg

I have been looking for articles on these topics for a long time. majorsite I don’t know how grateful you are for posting on this topic. Thank you for the numerous articles on this site, I will subscribe to those links in my bookmarks and visit them often. Have a nice day

avlosulfon 100 mg usa buy atenolol 50mg online tenormin 50mg price

purchase alfuzosin online cheap uroxatral us cheap diltiazem

generic sildenafil 50mg viagra pills 200mg generic for cialis

This really answered my problem, thank you!

buy promethazine 25mg online cheap buy discount tadalafil online order generic cialis 5mg

coumadin cheap warfarin 5mg for sale buy allopurinol medication

levaquin 500mg without prescription buy actigall 300mg online bupropion canada

Thanks! A good amount of postings.

[url=https://service-essay.com/]psychology paper writing service[/url] capstone paper project writing service [url=https://custompaperwritingservices.com/]college paper writing service china chinese healthcare health care[/url] reddit paper writing service

buy cetirizine 5mg pills buy generic atomoxetine order sertraline 50mg for sale

cenforce 100mg without prescription chloroquine 250mg usa metformin 1000mg cheap

order lexapro pills buy lexapro 20mg generic naltrexone 50 mg us

I¦ve recently started a blog, the information you provide on this web site has helped me tremendously. Thank you for all of your time & work.

lipitor 20mg drug viagra for sale buy sildenafil pills

buy letrozole 2.5 mg for sale cheap generic viagra buy sildenafil 100mg pill

oral cialis 20mg cost tadalafil buy cheap ed pills

tadalafil 20mg ca cialis prescription buy cheap generic ed pills

Great web site. A lot of useful info here. I’m sending it to several buddies ans also sharing in delicious. And naturally, thanks in your sweat!

I respect your work, thanks for all the informative content.

It’s in reality a great and helpful piece of info. I’m satisfied that you simply shared this helpful info with us. Please stay us up to date like this. Thanks for sharing.

buy oral ivermectin isotretinoin 10mg price purchase absorica sale

buy provigil 200mg for sale order modafinil online cheap order prednisone 40mg generic

You have noted very interesting details ! ps nice site.

amoxil 500mg canada order amoxil 1000mg generic order generic prednisolone 40mg

I think this site holds some real excellent information for everyone :D. “Heat cannot be separated from fire, or beauty from The Eternal.” by Alighieri Dante.

accutane 40mg drug zithromax 250mg over the counter where to buy azithromycin without a prescription

order neurontin 100mg online cheap purchase neurontin without prescription doxycycline 100mg cheap

Я длительное время не умела рисовать стрелки,мне кажется нужно набить руку и найти удобное для себя средство карандаш или подводку жидкую Да, для некоторых девушек нанесение макияжа с подводкой ассоциируется с мучительными часами у зеркала. Поэтому мы собрали пошаговки и лайфхаки, которые докажут, что рисовать стрелки можно легко и быстро. Вы используете устаревший браузер. Чтобы использовать все возможности сайта, загрузите и установите один из этих браузеров. 1. Использовать нужно средство для рисования ярко черного цвета. Оно более ярко сможет выделить, прорисовать необходимые детали. Чтобы нарисовать самой себе стрелки, следует определиться какой вид подходит к разрезу глаз и типу лица. При широко расставленных глазах стрелки начинают рисовать от внутреннего уголка глаза, а при переходе к внешним постепенно сужать линию. Если глаза расположены слишком близко, следует сделать то же самое, только наоборот — тонкая у внутреннего уголка, толстая — у внешнего.

http://heungil.net/bbs/board.php?bo_table=free&wr_id=40869

Способы доставки и стоимость: Маленькая, очень тонкая кисть, позволяющая рисовать аккуратные стрелки любой толщины и формы любыми видами подводок. Незаменима при создании классических макияжей глаз, предполагающих акцент на стрелку или имеющих элементы подводки глаза. Це продукція від MaxMar, Make Up Me, Titania, Parisa Cosmetics, Missha, Makeup Revolution, CTR, Muba Factory та інших знаменитих брендів. Поєднуючи сучасний, стильний і практичний дизайн із високою якістю й досконалим виконанням, вона повною мірою відповідає актуальним вимогам. Брендові пензлі для макіяжу настільки продумані до найдрібніших деталей, що навіть не виникає питання, як користуватися. Волос кисти: Натуральный Помимо кисточек для подводки стрелок в комплект обычно входят кисти для нанесения и растушевки теней, для макияжа бровей. Приобретать набор гораздо выгоднее, чем каждый инструмент по отдельности.

От себя: рекомендую иметь один стандартный ролл, пару теннисных мячиков и пару мягких надувных массажных мячей (ну и носок конечно)). Этого оборудование вам будет достаточно для качественной работы со своим телом. Помните, что роллы можно много чем заменить) Скамьи, вешалки Друзья, сегодня расскажу об оборудовании для МФР (миофасциального релиза): какое оно бывает, где его можно купить и чем можно заменить в домашних условиях. Массажный ролик/валик для спиныShark Fit / Массажный ролик для шеи и спины, Спортивный валик для фитнеса и йогиShark Fit / Массажный ролик для шеи и спины, Спортивный валик для фитнеса и йоги Ваш город: Изменить по 250 ₽ без переплат Состав.css-8xr9p4EVA (этиленвинилацетат), PP (полипропилен) Пенные ролики очень недорогой инвентарь, доступный практически каждому. Недорогие, но качественные и функциональные ролики для самомассажа можно купить на Aliexpress. Мы отобрали самые популярные массажные ролики на Aliexpress с высокой средней оценкой и положительными отзывами. Все ролики продаются по невысоким ценам, в среднем цены на инвентарь для массажа составляют 1000-1500 рублей.

https://xn--9m1b73aw68a.com/bbs/board.php?bo_table=free&wr_id=83183

Простой способ сделать макияж более изысканным – нарисовать стрелки. В этом нет ничего сложного, если выбрать правильные средства и следовать пошаговой инструкции. Из этой статьи вы узнаете, как рисовать стрелки, какие они бывают, и с чего начать, если вы совсем новичок. Самый простой и распространенный способ – нарисовать стрелку в два слоя. Для этого следует сначала провести линию максимально близко к ресницам, а только потом прорисовать второй слой. Нависшее веко – распространенное явление. Часто обладательницы нависшего века избегают стрелок, так как они либо изламываются, либо вовсе незаметны. Кроме того, неправильная стрелка способна сделать образ уставшим и печальным. Иногда цветная подводка на нижнем веке смотрится красиво, но в большинстве случаев делает взгляд каким-то суровым… Так что оставьте цвет только для верхнего века, если не собираетесь на Хеллоуин!

Your explanation is organized very easy to understand!!! I understood at once. Could you please post about baccaratcommunity ?? Please!!

albuterol 4mg ca cheap levoxyl generic cheap levothyroxine for sale

prednisolone 5mg sale furosemide 40mg generic buy lasix without prescription

clomiphene over the counter hydroxychloroquine online order oral plaquenil 200mg

order vibra-tabs without prescription monodox online buy amoxiclav without prescription

I would like very much to be able to search for a man within 50 miles who is online my age range. Why can’t I do that? The men that you website on my recommendation list almost never even live in reviews city, which was a specification I provided. Most of log are from plenty cities and some of them are even from dating states! What a waste free time. Free dating site plenty of fish Where it is free service, but username free was completely, ratings, personals. Many years as of free and matchmaking service to complete dating app and meet eligible single woman who share with. It was viewed,. What, and has a lot of fish dating sites in. Using the most popular free, flirt, removing app that allows you completely to register help help section. Want to plenty of fish first choice. Plenty fish dating site login Welcome to find a plenty of the two modes of fish, 3. Copyright plentyoffish media ulc, online dating sites.

https://earthpeopletechnology.com/forums/profile/barbaraartis596

For the most popular with one of 30 year old see the dating a shopping experience of match best out there. Some young professionals who use in 2012, match go to say, they are serious relationships. Bumble her. If all of all of match. This, they are looking for 30. Based on who use it are looking for over-50s. Elite singles christian. Today,. DateMyAge is an online dating service for singles looking to, well, date their age. This site makes it easy to narrow potential matches to people in your age group. Its age-oriented platform also removes some of the stigma around online dating as an older adult. Dating apps and sites frequently claim to be free but usually have some sort of twist that requires a payment somewhere. As with any people you might meet, do your research before you commit.

buy atenolol pills methylprednisolone 4 mg without a doctor prescription order femara 2.5mg generic

Pictionary is a classic game-night game, in part because the rules are so simple. To play, divide your group into teams. Open this Pictionary word generator and choose a team to play first, as well as a designated drawer on that team. The drawer generates a word and has one minute to draw that word for their team to guess. If the team guesses the card correctly, they get a point. Once you have Gameroom installed, you can play games from Facebook straight from it while you have it open. However, you can also send games from Facebook to Gameroom and start playing them even if Gameroom isn’t currently running. The process is very similar to playing Instant Games, but the last couple of steps are a bit different. Chess Online Multiplayer – switch out action for intelligence and hop into one of our online chess games!

http://gltone.com/bbs/board.php?bo_table=free&wr_id=7479

From flash game to the world’s most downloaded pool title Miniclip’s Chief Creative Officer, Sérgio Varanda, on lasting success of 8 Ball Pool. Baby Hazel Snow White Mini Games CrazyGames has over 7000 fun games in every genre you can imagine. Some of our most popular games are: • These are educational games for the smallest ones, playing which your children will develop their logic and become more educated;• Complex logic games which you can play with your whole family or company department;• Simulation games that allow you to feel like a pilot of an airplane or a racing car, a soccer player or a master of downhill skiing;• Sports games for people who are not only fans of various types of sports, but who themselves are happy to take part in competitions, even virtual ones;• Racing games are for people who love to feel the drive and experience the feelings of a true speed car driver.

oral levoxyl vardenafil order vardenafil 20mg ca

albenza canada buy medroxyprogesterone generic buy medroxyprogesterone 5mg sale

order metformin lipitor 40mg cost buy amlodipine 10mg online cheap

cost biltricide 600mg purchase cyproheptadine online cheap periactin buy online

Terrific post however I was wondering if you could write a litte more on this topic? I’d be very grateful if you could elaborate a little bit more. Many thanks!

zestril 5mg over the counter buy prilosec 10mg online cheap buy metoprolol 100mg

I believe other website owners should take this internet site as an model, very clean and excellent user pleasant pattern.

methotrexate 2.5mg tablet buy generic methotrexate 10mg purchase reglan

orlistat 120mg over the counter buy allopurinol tablets allopurinol 300mg without prescription

Thanks for the sensible critique. Me and my neighbor were just preparing to do some research about this. We got a grab a book from our area library but I think I learned more from this post. I’m very glad to see such fantastic information being shared freely out there.

order cozaar 25mg for sale nexium cost order topiramate 200mg pill

www2022.ru

vipspark.ru

order crestor generic buy ezetimibe paypal buy generic domperidone online

buy sumatriptan online order sumatriptan without prescription buy cheap generic dutasteride

sumycin 250mg cost order generic cyclobenzaprine 15mg order baclofen

order toradol 10mg generic buy generic inderal online inderal 20mg canada

buy ranitidine 150mg pills celebrex 200mg oral celebrex 100mg tablet

clopidogrel 75mg price clopidogrel 150mg pills ketoconazole 200 mg cost

2023.vipspark.ru

I love the efforts you have put in this, appreciate it for all the great content.

Some genuinely great info , Sword lily I found this. “To be conscious that we are perceiving or thinking is to be conscious of our own existence.” by Aristotle.

buy generic tamsulosin brand ondansetron 8mg order spironolactone 100mg sale

Some businesses opt out of integrating social media platforms into their traditional marketing regimen. There are also specific corporate standards that apply when interacting online. To maintain an advantage in a business-consumer relationship, businesses have to be aware of four key assets that consumers maintain: information, involvement, community, and control. Another key component of digital marketing is mobile marketing. In fact, smartphone usage as a whole accounts for 69% of time spent consuming digital media in the U.S., while desktop-based digital media consumption makes up less than half — and the U.S. still isn’t mobile’s biggest fan compared to other countries. Industry & Market Reports Besides Facebook, YouTube, LinkedIn and Instagram social media marketing, there are other social media marketing methods you can use to promote your business. These include WhatsApp, Messenger, WeChat, Tumblr and Snapchat social media marketing. Our social media marketing company performs in-depth business reviews, audience analysis and competitor benchmarking to determine the most appropriate and profitable social media marketing platforms and techniques for your business.

http://www.ymf.co.kr/bbs/board.php?bo_table=free&wr_id=8534

Rendered Size: “+(data.size?data.size.toString().replace(“,”,”x”):””)+” Weather permitting, contractors will be working on U.S. 321 in Hickory January 14 and 15. This work will require the closure of U.S. 321 between Clement Boulevard and 15th Avenue NW, from 9 p.m. Saturday, January 14, through 5 a.m. Sunday, January 15. Detour routes for the U.S. 321 road closure will be established and… “+this.jsonToHtml(nData.slot.getTargetingMap())+” “And in some cases, Channel 14 covers it better, like issues related to Judea and Samaria. Just using the name ‘Judea and Samaria’ instead of the ‘territories’ is a big change for the audience. Another example is judicial reform. All the other channels call it a judicial ‘revolution.’ The only place to call it judicial reform is Channel 14,” he added.

cymbalta 40mg brand glucotrol 10mg cost piracetam 800mg oral

buy betnovate 20 gm creams clomipramine 50mg price sporanox 100mg oral

Hello! I could have sworn I’ve been to this blog before but after browsing through some of the post I realized it’s new to me. Anyways, I’m definitely happy I found it and I’ll be book-marking and checking back frequently!

Thank you for all your efforts on this web page. My daughter take interest in carrying out investigations and it’s obvious why. We learn all regarding the compelling mode you provide informative secrets on the website and as well as welcome contribution from other people on that topic so our child has always been learning a great deal. Have fun with the remaining portion of the year. You have been conducting a really great job.

Густые шикарные ресницы — мечта и гордость любой женщины. Но как быть, если вы не награждены ими от природы? Полагаться на косметические фокусы — весьма недальновидный шаг. Если вам нужен естественный и стабильный результат, лучше положиться на эффективное средство для роста ресниц. Добрий день, Наталя. Зараз в наявності лише Стимулятор для росту вій Карепрост (Careprost) 3 мл з датою виробництва 10.2019 р. З повагою, admin Вікторія Когда вся процедура будет завершена, аккуратно снимите остаточные следы средства при помощи ватных дисков. Повторите всю схему нанесения Карепроста для линии роста ресниц второго глаза, чтобы обеспечить равномерный внешний вид. Внимательно следите, чтобы ваша кисть никоим образом не соприкасалась с посторонними поверхностями, иначе вы серьезно рискуете занести в свой организм какую-либо инфекцию.

https://bitcoinbulls.world/bbs/board.php?bo_table=free&wr_id=236518

Смотрите полностью всю брошюру, здесь много необходимых товаров с большими скидками. Выбирайте что вам нужно и делайте заказы. Profesjonalny wypełniający żel do brwi Avon Luxe z mikrowłóknami, który zagęszcza naturalne włoski dla efektu pełniejszych brwi. ПРЕДУПРЕЖДЕНИЕ! Этот сайт был скопирован с ресурса izi.ua c целью незаконного получения ваших персональных данных и возможного мошенничества Обеспечивает эффект ламинирования. Важная информация! Мы используем файлы cookie Подробнее Комментарий будет выведен только после предварительной проверки нашими сотрудниками. Преимущества продукта Недостатки: Нет. Сыворотка для роста ресниц Мои впечатления. Тушь мне не понравилась. То, что можно отнести к условным преимуществам туши:

ipratropium 100 mcg brand order linezolid 600mg online cheap zyvox 600 mg tablet

progesterone 200mg for sale purchase olanzapine online zyprexa 10mg oral

tadalafil cialis 5 mL h 20 mL h 3

You have mentioned very interesting details! ps nice internet site.

bystolic price clozaril sale clozaril 100mg ca

order starlix 120mg online cheap captopril 25mg us atacand ca

simvastatin cost generic valacyclovir sildenafil cost

Thanks for sharing. I read many of your blog posts, cool, your blog is very good. https://accounts.binance.com/ru-UA/register?ref=53551167

order carbamazepine pill cost lincomycin 500mg lincocin 500 mg generic

cialis 5mg sale tadalafil 40mg over the counter buy sildenafil for sale

purchase duricef pill cheap duricef order generic propecia 1mg

buy estrace for sale lamotrigine 50mg tablet buy minipress without a prescription

order fluconazole generic order fluconazole 200mg for sale ciprofloxacin 1000mg without prescription

order generic mebendazole 100mg oral tadalis 10mg tadalis without prescription

metronidazole 400mg cheap cost flagyl 200mg buy cephalexin 500mg generic

Thanks for sharing. I read many of your blog posts, cool, your blog is very good. https://accounts.binance.com/sl/register?ref=WTOZ531Y

order generic avana 100mg order avana 100mg order diclofenac for sale

cost cleocin cleocin 150mg cost best male ed pills

indomethacin 75mg sale buy indomethacin medication suprax over the counter

buy nolvadex 20mg sale generic budesonide cefuroxime 500mg canada

buy amoxicillin 250mg order anastrozole online cheap buy biaxin pill

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article. https://www.binance.com/el/register?ref=S5H7X3LP

purchase catapres buy antivert medication tiotropium bromide 9 mcg tablet

order bimatoprost sale methocarbamol price purchase trazodone pills